Test USB power supplies & ports - USB Type C & Power Delivery

Why should you test USB power supplies?

There are many manufacturers of USB power supplies, but these differ considerably in quality. The output power of a USB power supply unit varies depending on the USB specification and is clearly specified. However, not all manufacturers, especially those from China, do not adhere to the given standards. This can lead to battery damage and overheating of power supplies or mobile devices. This problem has existed for years, but the problem has increased significantly due to the new USB Type C interface technology.

What is USB Type C?

USB-C, also known as USB Type C, is the latest connector developed by the USB Implementers ’Forum (USB-IF) - a group of leading electronics companies such as Apple, Intel, Dell and Belkin. Since many of the world's best known manufacturers support this new technology, it is already being used everywhere. Thanks to this support, USB-C will gradually replace the previous USB types, i.e. USB-A, USB-B and USB Mini-B. The new connector brings numerous innovations, including USB Power Delivery.

What is Power Delivery?

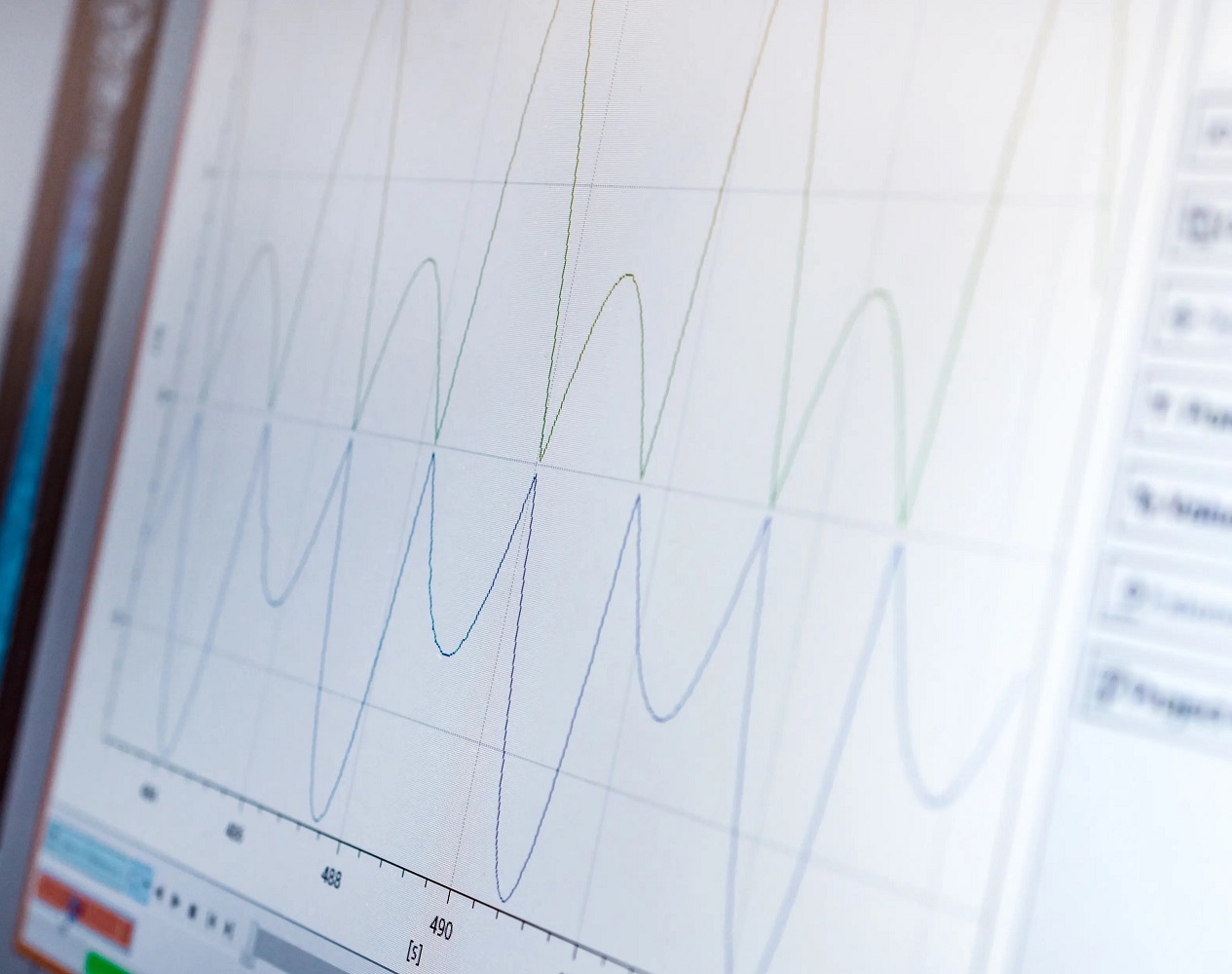

USB Power Delivery is a specification of USB that enables devices to be supplied with up to 100 watts. The voltage can be regulated for the first time with Power Delivery. Because of this, there are many advantages that speak in favor of implementing USB-PD, but also one major disadvantage: security.

What are the problems with USB Power Delivery?

Fast charging functions increase the risk of damage, as the power supply unit no longer simply supplies 5 volts DC. Instead, the power supply unit and smartphone negotiate up to 20 volts. If there are mistakes, there is a risk of expensive damage. USB PD is designed for up to 100 watts of power (20 V / 5 A). Electronically marked cables with a tiny chip in the plug are required for this. This tells the power supply how much current the cable can handle. Since USB-PD (Power Delivery) enables a significantly higher power output with regard to conventional USB charging standards, even small percentage deviations from the specification for cables or power supply units lead to problems, damage or, in the worst case, injuries. There have been numerous reports of burned-out or burned-out Type-C charging sockets, caused by untested no-name power supplies or cables whose resistances were incorrectly dimensioned and thus gave too much power.

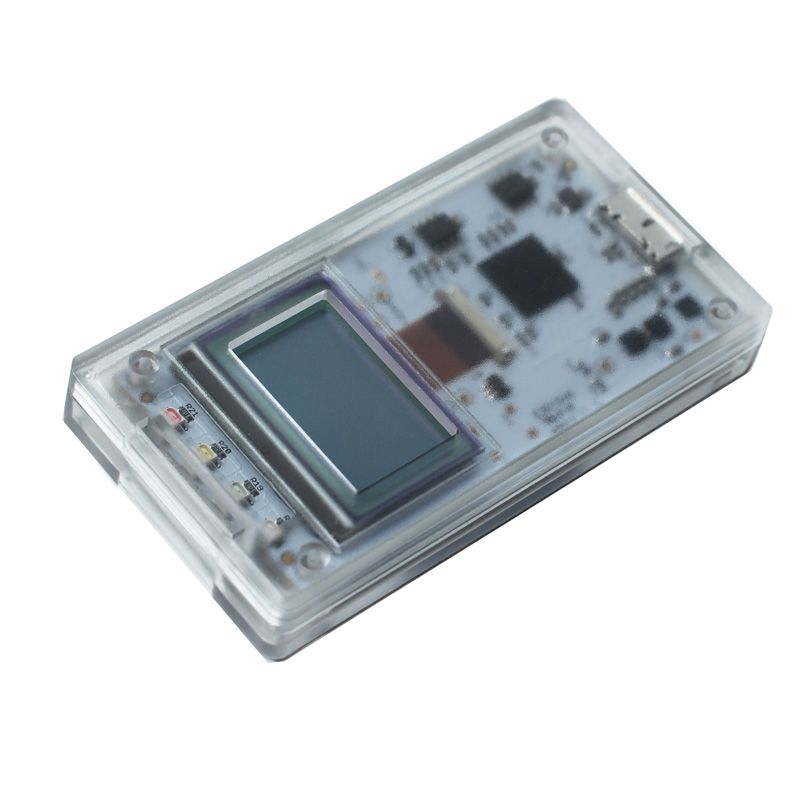

Testing of USB power supplies and cables

Due to the increasing dangers with the advancement of technology, it is of crucial importance to test USB power supplies as well as USB cables to ensure the safety and the avoidance of device damage. In the following we present devices for testing USB power supplies and cables according to the specifications.