Cable Test Service

Test reports

eVision Systems tests USB, HDMI & DVI cables for compliance with the applicable cable specification. Our tests are subject to strict framework conditions and are implemented with professional tools. For each tested cable you will receive a comprehensive test report. You can get an example of a test report result in the link below.

Register Demand

Register your testing needs to receive a quote with pricing information as well as information on the turnaround time. If you have any questions about the testing process or need more information about our cable testing service, you can use the form included in the link. Please include the number of cables, all cable types to be tested & your contact information.

Which cable standard can be tested?

| Testable cable types | ||||

| USB A Cable Types | USB A to C | USB A to B | USB A to Micro B | USB A to Lightning |

| USB C Cable Types | USB C to C | USB C to B | USB C to Micro B | USB C to Lightning |

| Video Cable Types | HDMI-A to HDMI-A | Displayport to Displayport | ||

What tests must a cable pass?

- Short circuit test

- Test for broken lines

- Continuity test

- DC resistance measurement

- Signal integrity check

- E-marker verification (Type C)

- Lightning function tests

- Overvoltage protection(Lightning)

- Voltage recovery (Lightning)

- Quiescent current consumption (Lightning)

Why should cables be tested?

Although the production costs of the cables are becoming increasingly expensive due to constantly rising complexity in manufacturing, the selling price of the cables increases only minimally. This is why the cable manufacturers are all based in low-wage countries. Due to the cost pressure, quality assurance measures are mostly missing and outgoing tests are only carried out to a very limited extent. Buyers and intermediaries are advised to take their own measures to verify the quality and functionality of the cables in order to prevent potential problems from arising in the first place.

Faulty cables, especially of the increasingly complex USB cable types, can lead to transmission errors and even dangers such as irreparable device damage or even device fires. Stress on support, expensive recalls and thus damage to the brand and reputation are consequences that can be avoided by a cable test. Especially with HDMI cables, which are expensive to manufacture, and USB cables, which are becoming increasingly complex, appropriate validation of specification parameters is important. An incoming inspection by sampling is usually sufficient.

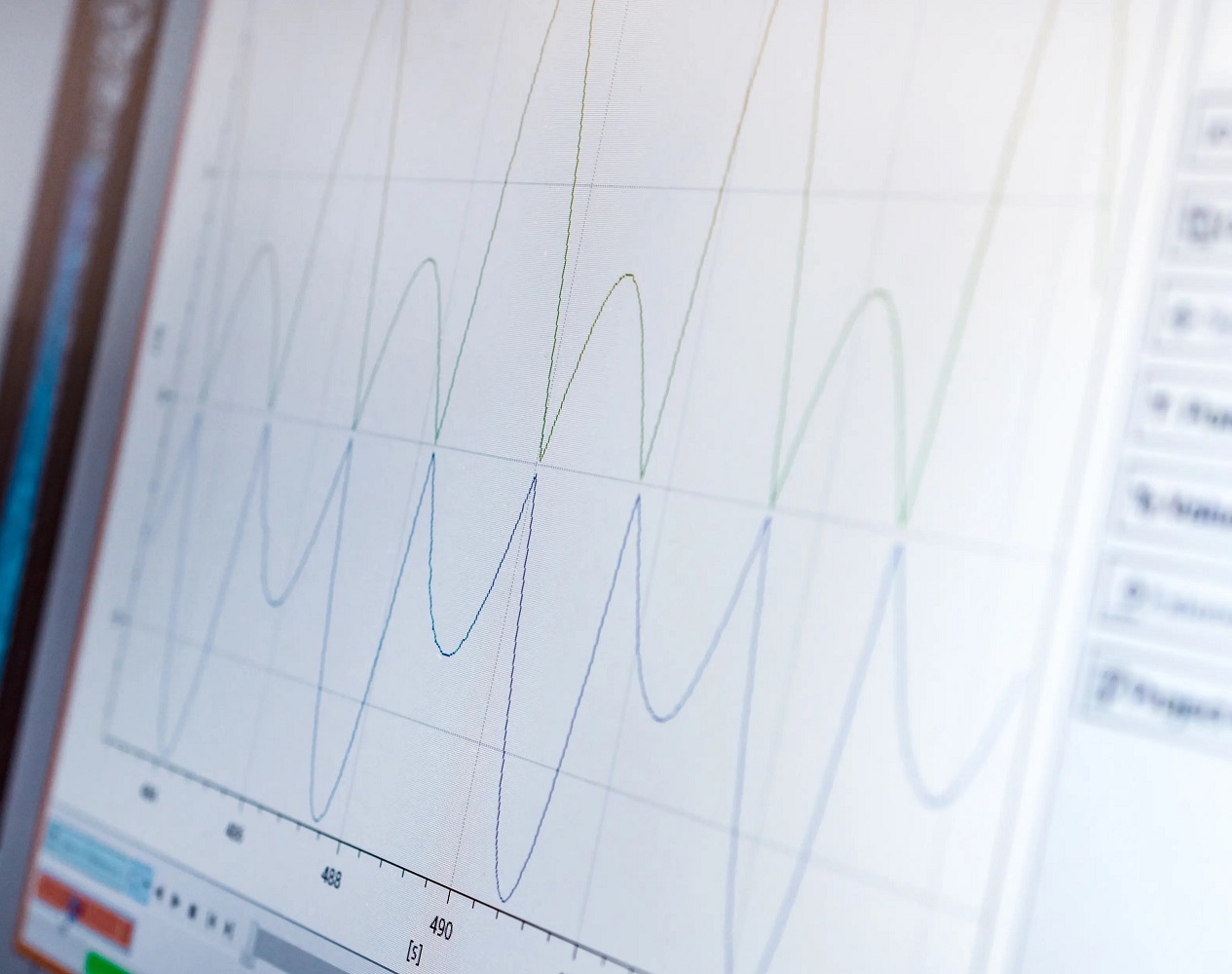

We test contact continuity, IR drop / DCR, e-marker data and signal integrity of the cables and provide the data in a single test report. Our testing has a signal integrity test that provides data and output of signals of various speeds with a coupling eye diagram of up to 12.8 Gbps. This provides companies with a much simpler and cost-effective way to verify the transmission quality of a cable. In addition, we are able to customize the test variables based on the applicable cable specifications. For our tests we use the cable tester ACTv2, which was developed in close cooperation with the USB Implementers Forum Inc. as well as Apple Inc.

The development of the USB specification

USB performance specifications

| Specification | Voltage | Current | Power |

| USB 1.0 / 1.1 | 5 V | 0.1 A | 0.5 W |

| USB 2.0 | 5 V | 0.5 A | 2.5 W |

| USB 3.0/3.1 | 5 V | 0.9-1.5 A | 7.5 W |

| USB BC 1.2 | 5 V | 1.5 A | 7.5 W |

| USB Typ C | 5 V | 3 A | 15 W |

| USB PD | 5 V / 12 V / 20 V | 5 A | 100 W |